The Stainless Steel type cable carrying line is a practical, efficient and safe festoon system for the distribution of energy required by lifting equipment such as cranes and overhead cranes used in various industrial sectors.

All the components of this Series, from the body to the screws, are 100% manufactured in AISI 304 and AISI 316 stainless steel.

This feature makes it especially suitable for the installation of lifting equipment in marine, chemical and foodstuff environments or in all those places where the presence of acids and corrosive substances could affect the functionality of the galvanised steel products.

Quality and benefits of stainless steel for the lifting equipment:

- Excellent corrosion and heat resistance

The presence of chromium, molybdenum and nickel dissolved in the alloy makes the steel rust-proof. In particular, the chromium contributes to the formation of a protective oxide layer that can regenerate itself, also when the material is subject to blows, cuts or a sub-zero temperature range. At the same time, the high resistance to heat means stainless steel can withstand very high temperatures, without deterioration or encrustations. - Variable hardness and ductility

The elasticity and ductility of stainless steel changes depending on the number of cold working and firing phases to which it is subjected during production. Every component of our festoon system cable carrying lines is manufactured following the most suitable machining process for the final purpose. - Stress resistance

The particular elasticity and ductility of stainless steel give this material high stress resistance, making it perfect for use in structures that envision impacts and pressures, such as overhead cranes, cranes and lifting installations.

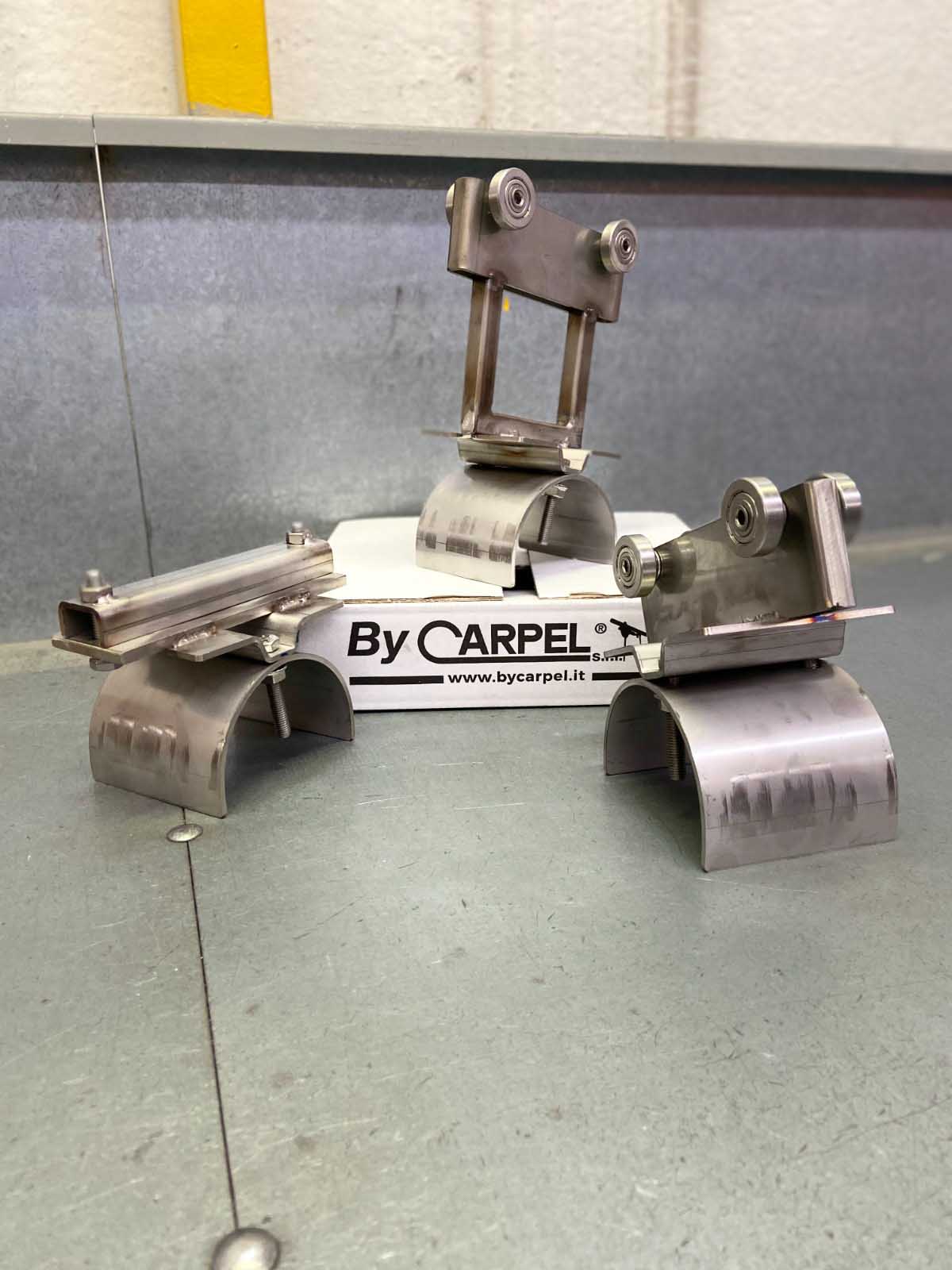

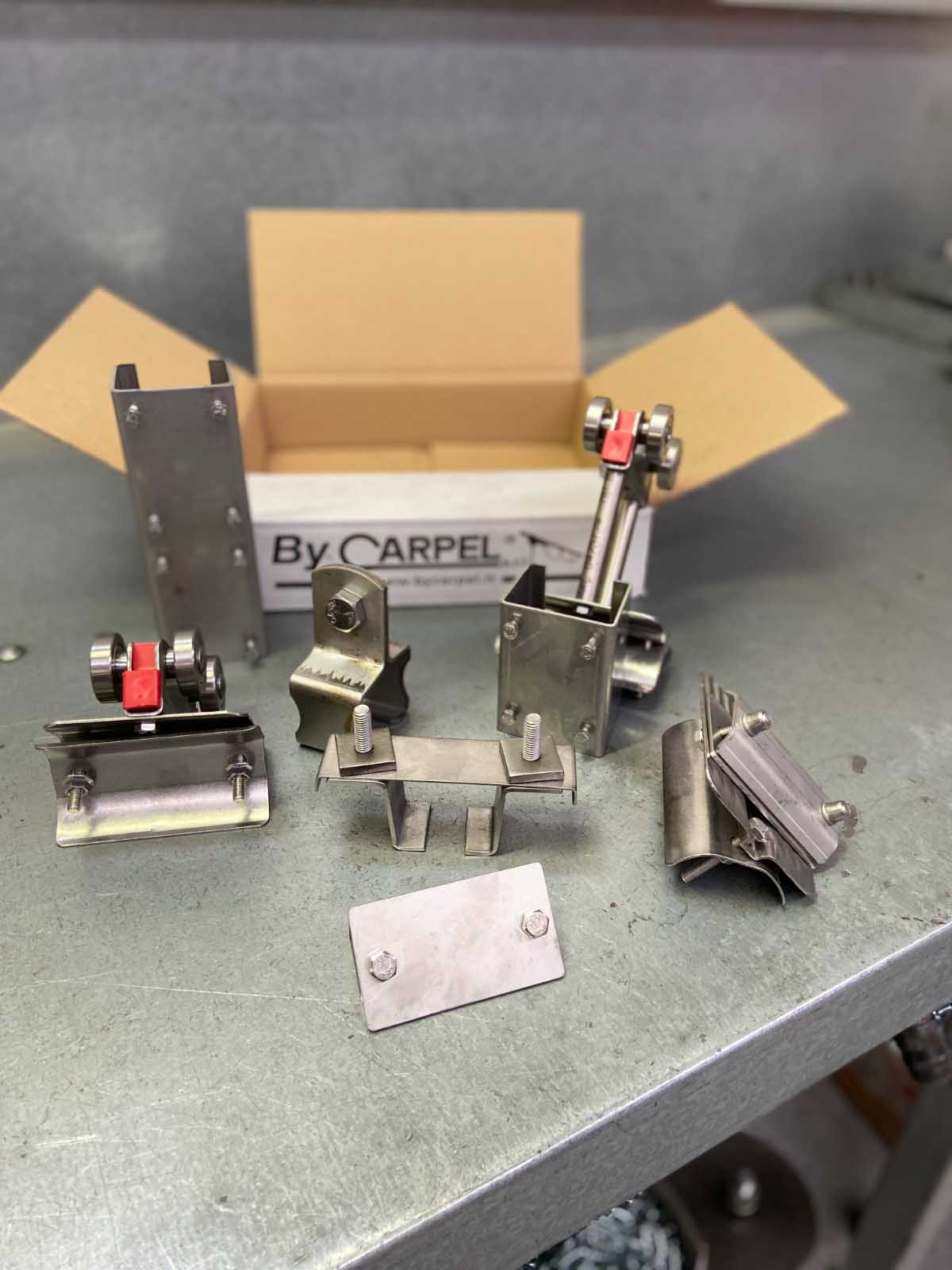

Components of the By Carpel Stainless Steel Lines: cable trough, square tube or IPE/NP beams, joints, suspensions, head with saddle, intermediate cable carrying system trolleys, trailer, head.

The By Carpel Stainless Steel type cable carrying lines are certified by the “CE” mark to guarantee compliance with the provisions of the Machinery Directive 2006/42/CE and as amended.